Compression Vs Tension | Example of Tension Force & Compression Force | Tension Force Formula

Compression Vs Tension | Tension and Compression In Bridges & Trusses | How Does Tension and Compression Work | Compression Force Examples

What is Tension Force?

Tension can be defined as the pulling force transmitted along the chain, string, a cable, or other one-dimensional continuous object or by each end of a rod, truss member or similar three-dimensional object; tension can also be described as action-reaction pair of forces acting at each end of said elements.

It is the force that tries to elongate a body or an object and the overall result in pulling away from the object.

Tension can be related to pulling on the ends of a rod and are often forces found on ropes, crane cables, nails, threads etc.

Tension Force Formula

When the structure has a constant velocity and in equilibrium, because the tension in the cable, which is pulling up the object, the tension force is equal to the weight force, i.e., mg.

M is a mass, and g is the acceleration caused by gravity, pulling down the object.

The Formula of Tension.

T = Mg

M = Mass/ Weight kg

g = gravitational force.

Examples of Tension Force

Tension forces arise when an object tried to resist change in its shape. For example, if two people pull a string from both sides, string applies tension forces. String hopes that its length will remain constant.

The cable that supports the lift experiences tension. Cable has no motivation to transport humans, it is just trying to maintain its length.

Tension is developed in the rope during a game of tug of war.

What are Tension Force examples?

1. Rope

When you are holding a rope from the center, the portions of rope that are on either end of your hand feel a tension force.

This is because the length of each piece of rope has been decreased by using gravity to pull it down towards the ground.

2. Building Structures

When you build structures, such as houses and bridges, tension forces are put in place so that they can withstand harsh weather conditions and other natural hazards which can cause problems for people living in certain areas around the world.

3. Building a Rope Bridge

When you are trying to construct a rope bridge, tension forces must be applied using the various sections of rope in order to make a strong structure which will not break under the weight of people walking across it.

4. Elevators

Elevators are designed so that tension forces are applied to each piece of rope which is attached to the elevator.

This is because the weight of the elevator causes a compression force which pulls on each piece of rope.

Therefore, the tension forces which have been put into place must also be strong enough to withstand this compression force in order to keep the elevator from falling.

5. Dental Floss

Dental floss is very light in terms of the weight it can withstand, which means that tension forces are necessary in order for it to be able to support the weight of a person’s teeth.

6. Chords Colliding

When different chords collide together, they create waves of sound which travel through the air and eventually reach your ears.

This is because each chord produces a sound wave which will bump into another chord and cause its frequency to be increased or decreased.

7. Rock Climbing

When you are rock climbing, a rope is attached to different parts of your body in order to keep you from falling down the side of a mountain.

Because of the weight that is being put on the rope, tension forces must be applied so that it does not break and cause you to lose your life.

8. Bicycle Chain

If a bicycle chain were not designed with tension forces in mind, then it would become too loose when used for riding purposes.

This is due to the fact that when a bicycle goes around, it causes the chain to move from side to side.

If there were no tension forces on the chain, this would cause it to move too far and not be able to support the weight of the bike.

9. Balloons

After you blow up a balloon, you can see that it is slightly curved inwards at all of its parts. This is because the internal pressure which is produced by blowing air into it creates a compression force within the balloon.

The tension forces that are being applied must be strong enough to counteract this compression force and create a shape that will be strong enough to hold the air inside of it.

Other Examples of Tension Forces

- The tension of the rope can be used to draw water from wells through pulleys.

- Cables from helicopters are used for rescue missions, to lift people, or heavy equipment.

- The tension of the cables are used for rock climbing or scaling rough terrains.

- Elevators use cables that can withstand high tension forces.

Compression Forces

What is Compression Force?

Compression can be defined as a force that presses inward on an object or structure, resulting in an object being compacted. It is the force that attempts to shorten the object or structure.

When the object in compression, the force acting on it is directed towards the body and is associated with pushing the ends of a road toward the middle. An example is a concrete beam the weight of the structure acts on it by transferring its weight.

What Is Compression Structure

A compression structure is any engineering structure that is used to compress or constrain a material or object to reduce its volume or size. A compression structure is any building, bridge, or other form of construction that uses compression as a support principle.

It’s most commonly detected by walking on the ground and feeling a sense of pressure or compression.

Buildings are also subject to compression as well, but this is usually detected by looking at the roof of the building and noticing a scissor-like effect.

Compressions structures may be made of any material that can resist compressive forces, such as metal, wood, concrete, or plastic.

What is Compression Member in Construction?

Compression member is a structural member of a building, often made of metal, which provides support against the force of compression. Compression members are often composed of many linear struts that are linked together, and the struts are often installed directly onto the supporting surface.

Compression members are used in both the exterior and interior of buildings, and many varieties exist and are used depending on the type of building and its construction.

Different types of compression structures exist for various applications. Hydraulic fill systems use water or oil to compress material from an excavated site, with water-tight tanks used to store the material.

A screw press is a simpler and more straightforward compression structure that works by turning a screw, which forces material into a die.

Compression Force Examples

What are some examples of Compression force?

A Sponge

The pressure forces of a sponge are caused by the tension and compression of the varying volume of water which makes up the sponge.

The water compresses and stretches as it is squeezed, thus allowing the sponge to expand or burst when you are squeezing it.

On occasions, this cannot be avoided, and this can be seen when we squeeze a sponge in our hands; however, if you think about it logically, you might see that you actually create pressure within your hand because of the body weight that presses down on your hand.

Plastic Bag

If you place a plastic bag on the floor, bend it in a specific way, and then release it from the floor, you will see that it bounces back up again.

This is because of the compression force caused by the weight of the bag which is supporting itself against gravity.

When you remove a heavy object such as a book or an umbrella from a table, this causes the weight of this object to decrease and thus also causes the pressure to decrease. This may be because of the fact that you no longer have to support that weight, thus causing a decrease in pressure.

Hanging Rope Example

When a rope is hanging from above, it causes more pressure on the floor than it would if it were lying on the floor. This is because gravity is pulling down on the rope which causes an increase in pressure.

If you think about it normally, you will see that there is more weight on one end of the rope than there is at the other end because of gravity’s pull.

Therefore, the magnitude of the pressure which is acting on the floor is greater than if it were lying flat on the ground.

Bicycle Pump

When you use your bicycle pump, it receives a constant force from both tension and compression. This is because the constant rotation of the bicycle pump causes the wheel’s spokes to rotate at different speeds, which results in compression and tension forces on the bicycle pump.

Spring

The tension and compression forces are experienced by any elastic object, whether it be a bead, a drumhead, or a rubber band.

A rubber band is the best example of elasticity and how it compresses and stretches at different points. Elastic objects are designed so that they can return to their original shape when they are in contact with each other.

Hydraulic Press

A hydraulic press is used to compress a block of metal. The force which is exerted by the hydraulic press is caused by both tension and compression.

The force acts on the block from the bottom of the press and causes it to be compressed further into shape.

These compressive forces are applied in order to force a piece of metal from its original shape into one which requires a thinner piece of metal for use.

Pneumatic Tire

When you are driving your car, your tires experience both tension and compression forces as they move around in circles.

This is because the weight of the vehicle causes pressure on the tires being used at a given time, which results in a compressed or stretched tire depending on whether or not it is under pressure.

Stretching Rubber Band

If you stretch a rubber band, you will see that it will begin to have a curved shape after being stretched for a short period of time.

This is because the rubber band initially resists stretching and then grows more flexible as it stretches. This is how rubber bands are able to stretch without breaking, whereas steel beams are not able to stretch at all and tend to break easily when distorted by stress.

Atmospheric Pressure

The atmospheric pressure of any given location is what causes wind to blow at different speeds at different locations, which results in an influence on different weather patterns all over the world. This is because of the pressure exerted by the atmosphere that is found at different locations.

Compression Vs Tension

Compression |

Tension |

|

| 1 | A compression force in a structural member is a force that squeezes material together. | A tension force in a structural member is force that pulls materials apart. |

| 2 | The type of force that attempts to shorten the body or an object is called Compression Force. | The type of force that attempts to elongate a body or an object is called Tension Force. |

| 3 | Effects of compression force is pushing towards the structure or object. | The effect direction of force in tension in the structure is outward from the object. |

| 4 | Compression is associated with pushing on the ends of a structure or rod toward the middle. | Tension force is associated with pulling on the ends of a structure or rod |

| 5 | Compression can be used to the transference of force in the hydraulic system as pressure | Tension is a force promulgation method. |

| 6 | Compression in structure is applicable to any material including concrete | Tension force is only applicable in solid strings |

| 7 | Compression in the structure is considered as a phenomenon | Tension in the structure is considered as a force. |

| 8 | Examples of compression forces are in concrete pillars when structural load acts on them | Examples of Tensile forces are in ropes, threads, the cable of crane and nails. |

What Is the Difference Between Tension and Compression Forces?

Tension and compression forces are two different ways that we can change the shape of a material. Tension is pulling on both ends of something in opposite directions, while compression is pushing inwards from all sides.

Tension forces are the opposing forces that pull on an object, like a rubber band. Compression is the force opposite of tension and is created by pushing together or squeezing an object.

With compression, all parts of an object feel pressure equally – whereas with tension, there is greater pressure on one side than the other.

These forces can be applied to solids but they work differently depending on the type of material. For example, if you were to push inward with your hands on an inflated balloon it will deflate because air moves out when there’s pressure against the surface of it.

But if you pull outward on one side then push inward with your other hand it’ll inflate because air flows into the balloon when there’s tension going across its surface.

Tension and Compression in Truss

A truss is a structure used to provide support and stability to a stabilized span. A truss is often engineered of straight, rigid elements (bars, rods, or beams) arranged in triangular patterns.

These rigid elements are connected at all joints to transmit the loads of the structure, stresses and strains, to adjacent members.

The tension in a truss occurs when the members push against one another to create a stable framework.

The compression in the truss occurs when compressing forces push in opposite directions on the members of the truss.

Tension and compression are two important forces which are present in a truss. When the forces are balanced in the truss, the truss is in equilibrium and when the forces are not balanced the truss is out of equilibrium.

The tension and compression in a truss can be determined by measuring the reactions at joints. The tension is the force that pulls away from the joint and the compression is the force that pushes towards the joint.

Tension and Compression In Bridges

Bridges are constructed through the use of tension and compression. Bridges are made out of a combination of tension and compression.

There is tension that is created at a bridge’s support points, and compression is created when the bridge spans across a body of water.

This is because steel is weaker in compression than tension, so the bridge’s main support towers will bear more weight from the compression, and the water will be pushing against the bridge’s foundations with a level of tension.

To understand tension and compression, let’s take a look at a suspension bridge. This type of bridge has cables that are anchored on one end and stretched across the middle to the other side.

As the pedestrians walk across the bridge, the weight of the pedestrians combined with the height between the two cables causes the cables to stretch and pull away from one another. The cables are in tension and they are stretched at that point.

Now, as the pedestrians get to the other side, the tension is released and the two cables come together. What happens when a person crosses? The cables move apart and become taut.

What is the function of the cables? The cables function to provide support to the bridge and to prevent it from collapsing. The tension and compression are what causes the suspension bridge to work.

Bridges are put together by similar means as a suspension bridge, only instead of tension and compression, there is tension in compression.

How Does Tension and Compression Work In Truss/Beam Bridges

As bridges are designed to span a long distance, they are built from large beams that must support the weight of the bridge and anything that crosses it.

The weight can be distributed among the beams through a process called compression. The beams are under immense pressure when a load is placed on them, and this pressure can make them buckle slightly in the middle.

This strain is called compression. The beams also have to support the weight from the side as well, and this strain is called tension. Tension is the strain placed on one side of a beam when the other side is compressed.

Bridges are designed to use realistic weights in order to test how much strain is put on a beam at a given weight.

This way, engineers can make sure that the weight of the bridge will support itself in the event that it fails.

Tension and Compression in Beams and Trusses

Compression and Tension Forces

The ropes and cables in a suspension bridge work in tension force, not compression. When a materialist pulled, it’s in tension. When it’s pushed or squeezed, it’s in compression.

Hanging deck of a suspension bridge pulls on the vertical ropes, then pull on the main cables, placing them intention while under tension. The main cables pushed down on the supporting towers, placing them in compression.

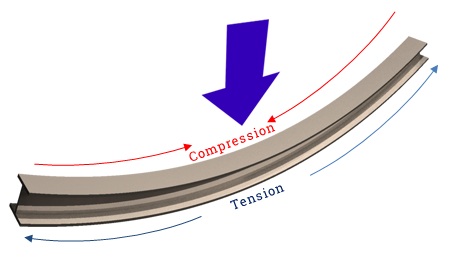

Bending

When like an I-beam or rod bend, it means it is are under tension and compression forces at the same time. For example, consider the I-beam below:

The top of these beam is under compression force while the bottom side of the beam is under tension force. The line running along the center of the beam is not under compression or compression.

The top and bottom of the I-beam are made thicker because these are the areas that experience the most force. Since stress is the force per unit area, having a large surface area allows for the stress on the ends of the beam to be reduced.

Compressive and tensile forces are present in all bridges, and it is the job of engineers to design bridges capable of withstanding these forces without buckling or snapping.

Buckling occurs when compressive forces overcome an object’s ability to handle compression, and snapping occurs when the tensile forces overcome an object’s ability to take tension.

The best way to deal with these forces is to either dissipate them or transfer them. To dissipate force is to spread it out over a greater area so that no one spot has to bear the brunt of the concentrated force. To transfer and force is to move it from weakness to an area of strength, an area designed to handle the force.