Expanded Polystyrene EPS Technology: Advantages and Disadvantageous of EPS Technology in Construction

EPS Technology |How is Expanded Polystyrene Foam Manufactured? | Expanded Polystyrene (EPS) in Construction | EPS Wall Panels Disadvantages

What is the Expanded Polystyrene (EPS) Technology?

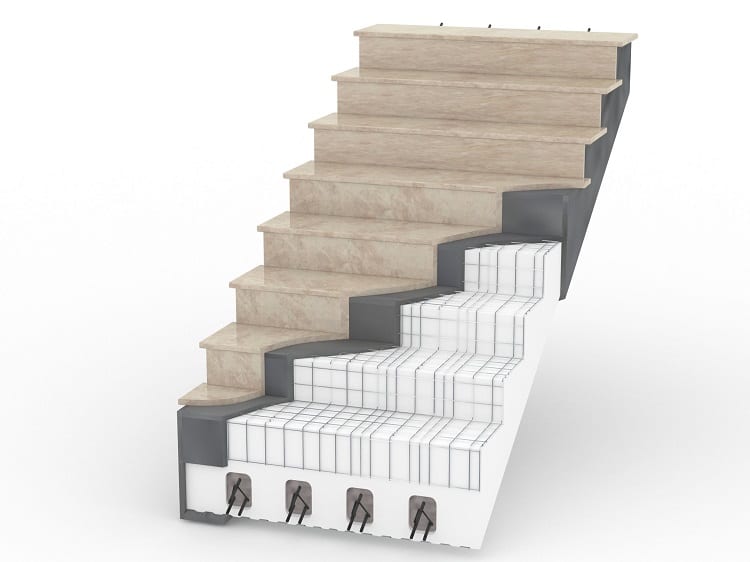

The expanded polystyrene (EPS) technology involves the construction of houses by assembling ready-made EPS foam, sandwiched between a galvanized steel wire mesh that is plastered on both sides with concrete.

Expanded Polystyrene is a lightweight insulation made from expanded polystyrene and it is used in construction to create walls and roofs for buildings.

The Expanded Polystyrene Material EPS insulation is made from polystyrene beads that are fused together before being expanded.

The material is lightweight, fire-resistant, and a great insulator. Advantages of EPS technology Expanded Polystyrene technology is energy efficient, environmentally friendly, and recyclable.

It provides lightweight, fire resistant insulation for homes, buildings, and other structures. Expanded Polystyrene can be recycled when it’s done being used.

Expanded Polystyrene is a thermoplastic material that will not corrode over time. EPS is an excellent building material because it doesn’t rot, dissolve, or corrode.

Steel and concrete are completely different in their properties and that is why their usage changes in construction.

How is Expanded Polystyrene Foam Manufactured?

Expanded Polystyrene foam is manufactured from the by-products, or left overs, from the oil refining process. FPM is a “Block Molder” of EPS which means we mold EPS into large blocks 36” x 48” x 120” in size.

These blocks are then cut into smaller usable sizes that vary with the application. The description below explains how manufactures the EPS foam pieces and sheets you are familiar.

Buys raw material in the form of resin or beads of styrene. Each bead has a microscopic dot of Pentane formed into its center.

This material is furnished in air tight bags. These bags keep the beads “fresh” by assuring that the Pentane within each bead cannot escape into the atmosphere and render the material. These beads of Styrene are about the size of a grain of salt and have a similar consistency.

It is crucial that the beads are stored in a tightly controlled environment where the amount of Pentane within their plastic shell remains consistent. Each step of EPS production requires strict adherence very tightly controlled quality standards.

These beads of resin are loaded into a machine called a “pre-expander”. It does exactly what the name implies. Steam is injected into the beads at 212 degrees F.

The heat accomplishes two things. The wall of each bead is softened and becomes flexible and the increased temperature also causes the Pentane to expand within the softened beads. The beads puff up like popcorn to 30 times their original size.

The next step is the molding process. It is at this point that the individual expanded beads are molded into a single, homogeneous block. This is the most crucial stage in the production process and it is essential that very strict quality control standards are adhered.

There are usually single panels that can be used to construct up to 4 storeys and double panels that can be used up to 20 storeys.

Expanded Polystyrene in Construction

Expanded polystyrene (EPS) is an innovative building material that lends to the design and structural integrity of many building projects.

EPS has been recognized as a mainstream insulation material, however over the past decade, new applications have rapidly developed.

EPS is a powerful design element and an ideal choice for green building design, offering tangible environmental advantages that can maximize energy efficiency, providing improved indoor environmental quality and enhancing durability.

EPS pre-fabricated systems are generally comprised of a series of interlocking panels, each of which is basically a sandwich of grey EPS bonded between a specified outer and inner board material.

Pre-fabricated systems are generally comprised of a series of interlocking panels, each of which is basically a sandwich of grey EPS bonded between a specified outer and inner board material.

EPS blocks are extensively used in the building industry to insulate walls and floors, as well as in the packaging business, where pieces with basic forms may be hot wire cut to protect corners and edges.

Using this EPS as a component of a pre-fabricated building system can also help reduce CO2 emissions associated with transporting building components to construction sites, as EPS is an exceptionally lightweight solution for a wide variety of building applications.

Advantages of Expanded Polystyrene (EPS) Technology

EPS materials are frequently used as insulation for walls, foundations, and roofs. There are several advantages to using EPS Technology;

EPS Is Eco-Friendly

Being a manufactured product, EPS are very eco-friendly by ensuring minimal degradation of the natural environment that is heavily impacted by mining stones in quarries. There will be minimal construction waste as EPS is recyclable and Reusable.

Shorter Construction Period

Buildings take a shorter time to construct. When using the EPS technology, a building takes a very short period of time before the occupation.

It Is a Mature Technology

Since it has been in use in Europe and the United States for nearly three decades, the building has been built in the United States with 44 floors.

Therefore, this technology has formed a system, and the bonding layer, the thermal insulation layer and the finishing layer can be used together, and there are many more mature technical documents.

Has Good Insulation

EPS is undoubtedly an excellent thermal insulator. Often used in the building industry to insulate external walls, partition walls between apartments, and also, in a more dense form, for structures such as ceilings, terraces, and roofs.

Because the insulation material uses expanded polystyrene, its price is not very expensive, making the whole system affordable. User-friendly.

Easy Construction Process

There is no complicated construction process. After a brief training, the general construction unit can master the construction essentials and facilitate the promotion of technology.

Design Flexibility

With this technology, a developer can implement virtually any building. What the developer only needs to do is just to think and be creative

EPS is More Safer

They have a higher resistance hence are safer during huge impacts such as earthquakes and tremors.

Soundproof

The EPS panels are also soundproof that allows for some confidentiality and keeps away noise pollution.

Disadvantages of Expanded Polystyrene (EPS) Technology

Low Bearing Capacity

Due to the nature of the board itself, its strength is not high, the bearing capacity is low, and the external facing brick needs to be strengthened.

Potential Defects in Manufacturing

The board has to go through a period of maturity before leaving the factory, it needs to be placed for a period of time before it can be used. If the curing time is insufficient, the quality of the sheet cannot be guaranteed, and the sheet shrinks after construction, causing the system to crack.

Poor Combustion Performance

EPS material causes it to remain at an abnormal level, Beijing Radio’s fire is caused by the extremely low combustion performance of EPS.

Not Environmentally Friendly

EPS is not environmentally friendly in the production process, it will eliminate a lot of waste and gas, and has a great impact on the surrounding environment.

Poor Thermal Conductivity

Poor thermal conductivity resulting in not meeting the current 75 energy-saving standards promoted in China, basically EPS belongs to the insulation materials being eliminated.

EPS Can be Expensive

The price of the EPS panels is slightly expensive compared to the traditional building materials that may impact on the overall construction cost.

Require Screed/ Plaster

The EPS panels require screed/ plaster on both sides of the panel that may increase the cost of construction.

Needs Specialized Labor

The labor required to construct using the EPS panels is scarce and thus more expensive.

Interested

Am interested in this technology for a 3 storey building.